Griddle

| Griddle | |

|---|---|

Commercial gas-fired griddle | |

| Classification | Cooking Equipment |

| Industry | Various |

| Application | Cooking |

| Fuel source | Natural Gas, Propane, Electric |

A griddle is a cooking device consisting of a broad flat surface heated by gas, electricity, wood, or coal, with both residential and commercial applications. In industrialized countries, a griddle is most commonly a flat metal plate, elsewhere typically a brick slab or tablet.[1][2]

In developed cultures a residential griddle may be composed of cast or wrought iron, aluminum, or carbon steel. The vast majority of commercial grade griddles are made from A36 steel, though some are stainless steel or composites of stainless and aluminum. Almost all residential and commercial griddles are heated directly or indirectly by flame or electrical elements.

Traditional

Traditional griddles include a stone or brick slab or tablet, and a shallow platter filled with sand. The former are usually heated to cooking temperature before the food is placed on them, the latter heated after.

In Latin America one traditional style of griddle is a budare. Made from stone or clay, it is used to cook a variety of flatbreads, such as tortilla, arepa and casabe. Modern versions for commercial use are metal and called comals.

The metal griddle is usually made of aluminium, stainless steel or cast iron. Metal griddles originally were a flat metal surface for frying suspended from hooks over a campfire or fireplace. Later versions were sometimes integrated into the tops of wood-fired cookstoves as a removable iron plate, and later as a separate, typically handle-less plate covering one or more burners on a gas or electric stove.

The traditional Scottish griddle (or girdle), found also in the UK, has a flat wrought iron disk with an upturned rim to which a semicircular hoop handle is attached, allowing it to be suspended over the fire from a central chain and hook.[3] Girdles are used for cooking scones, bannocks, pancakes and oatcakes.[4][5]

The traditional Welsh griddle is similar, circular with a one-piece handle, typically cast iron, 1 cm (½ inch) in thickness. It is used to cook Welsh cakes, pikelets, and crepes.

Residential

In residential applications a griddle may be composed of cast or wrought iron, aluminum or carbon steel typically 1/16 to 1/8-inch (1.6 to 3.2mm) thick. Portable electric units with limited temperature control are most common, often with Teflon or other stick-resistant coatings. These units are highly portable and suitable for light-duty cooking. Portable griddle plates are commonly used on one or more gas or electric cooking zones (a single zone unit may be considered a "frying pan"). Premium brand residential ranges offer griddle top options as well, which look much like those on commercial grade ranges.

Commercial

Commercial grade griddles may be either free-standing countertop equipment that sits on a stand or base, or part of a larger piece of equipment such as a restaurant range. Most units are 24 to 72 in (610 to 1,829 mm), in increments of 12 in (305 mm). All have three components: a plate, heat source, and temperature control. Performance, such as time to heat, temperature consistency/evenness, recovery time, and productivity (pounds of food per hour),[6] reflects how they are combined.

Each of these primary characteristics can dramatically affect the performance of the overall unit, with the distinguishing feature being a large, flat, cook surface. Some foods are cooked or scorched using a dry heat, but the most common technique is shallow frying, where an item is either cooked in a relatively thin film of added oil or its own renderings.

Leftover fat and residual debris are scraped off into a trough, most commonly in front but also on the side and rear, thence through a chute into a can or tray. Commercial griddles typically have “splashes”, 3 to 5 in (76 to 127 mm) vertical metal shields that catch flying fat and prevent items from being pushed off.

It is difficult to distinguish on sight a basic griddle from one with more sophisticated construction and dramatically superior performance. Manufacturer specification sheets provide particulars.

Plate material

The vast majority of commercial grade griddles are made from A36 steel from 3⁄8 to 1 in (10 to 25 mm) thick, though some are composed of stainless steel or even composites of aluminum and stainless steel of varying thicknesses. Griddle plate depth (front-to-back) is typically 24-inches (610mm), though compact units may be as shallow as 18 in (457 mm), and deep units can be up to 30 in (762 mm) in depth. Typical commercial gas griddles have plates between 3/4 and 1-inch thick (19 to 25mm). Electric griddle plates are typically thinner, from 3⁄8 to 1⁄2 in (10 to 13 mm) thick, to reduce the response lag between the control and plate surface common in such designs (less material improves heat transfer time).

Because most commercial griddle plates are made from the same material the heat transfer characteristics of a griddle plate can commonly be inferred from its geometry. A carbon steel plate heated by an array of U-shaped or H-shaped burners does not distribute heat in a perfectly even pattern, even if all thermostats are set to the same temperature and are perfectly calibrated. As a result, temperature ‘islands’ can develop on the griddle plate surface, resulting in measurable hot and cold spots that can affect griddle performance.[7]

Composite

Composite plate material can be a combination of any two dissimilar metals to optimize heat transfer characteristics and improve griddle performance. A common variant of this construction, currently available, involves a core of aluminum laminated with type 304 stainless steel[8] on either side. The heat transfer rate of aluminum is five times that of carbon steel, which maximizes heat transfer from the bottom of the plate to the cooking surface, and facilitates an even temperature distribution over the entire plate surface regardless of heat source. Type 304 stainless steel is medical grade,[9] with a low level of porosity that reduces the penetration of cooking products into the surface, which causes sticking and flavor transfer – important performance metrics for commercial applications. This tends to significantly improve surface cleaning characteristics, especially in a commercial cooking environment, which can reduce cleaning labor and the need for consumable cleaning products.[10]

Because aluminum is only one third the weight of steel, griddles manufactured with an aluminum/stainless steel composite material tend to be substantially lighter, which facilitates installation and movement of the griddle.[11][12]

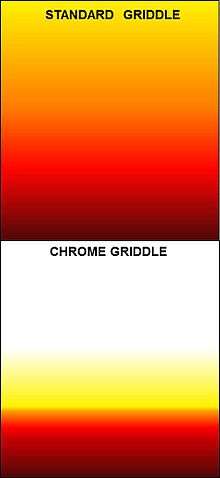

Chrome

Chrome plating is a relatively common variation on surface finish for commercial griddles. The finish is aesthetically pleasing, but offers additional benefits to griddle operators. In its plated form chrome is non-porous, impermeable and non-reactive (inert) with food products, which limits food sticking during the cooking process and facilitates cleaning, as well as reduced flavor transfer between foods. The mirror finish of a chrome finish reduces heat transmission to the environment due to the low surface emissivity, a characteristic common to most highly polished surfaces.

Chrome surfaces can be damaged by cleaning with abrasives and sharp/hardened metal utensils common in commercial cooking environments, so special spatulas, brushes and cleansers are recommended for the operation and maintenance of these products. If damage does occur to the chrome surface, food acids tend to penetrate and dissolve the metal substrate beneath the chrome coating, causing it to spall off. Chrome griddles can be cleaned with soapy water and a palmetto bristle brush. Metal scrapers and abrasives should be explicitly avoided, as they tend to damage the surface and permanently cloud the mirror finish. Special cleaning agents and powders specifically for use on chrome surfaces are also available.

Chrome plating can be done by two different methods, where the source of the deposited metal is either in the form of hexavalent chromium or trivalent chromium. Hexavalent chrome plating baths have a long history for producing heavy, corrosion resistant and mechanically hard coatings. However, the process is slow, varies in thickness according to the shape of the object, and produces extremely toxic waste. Plating from trivalent baths is commonly used for thinner, decorative finishes. It can be faster, more uniform, and with lower disposal costs but requires more careful controls during the process.[13]

Heavy chrome plating, known as “hard chrome” from hexavalent baths, is the more common form used on commercial griddles. As plating thickness is increased, the surface finish of the underlying steel must be smoother, as the plating does not have a leveling effect.[14] Also because chrome plating is so hard (65 to 69 Rockwell scale), it is subject to damage if the underlying surface deforms during impacts from metal spatulas or pots and pans. Consequently, a quenched and tempered alloy steel such as A514 is frequently used for commercial cooking applications. That type of steel has three times the yield strength of common structural steel such as A36 which might otherwise be used for griddles.[15]

Grooved surfaces

Grooved griddle surfaces are a common plate modification for commercial applications. Typically done to allow a sufficiently hot griddle to create branding marks similar to what might be found on a grill, but without the need to maintain two pieces of equipment for that purpose. The geometry of the grooves is typically unique for each manufacturer, and tapered from the back of the griddle plate towards the front to facilitate the drainage of grease and other fluids. Effective cleaning of a grooved griddle can be performed with a wire or palmetto bristle brush, and many manufacturers provide a custom scraper designed to fit the geometry of the groove pattern.

Griddles can be partially or fully grooved according to the needs of the customer, though extra care needs to be exercised when applied to griddles with embedded thermostats where the web thickness between the thermostat slot and top-side groove could result in breakthrough of the plate material.

Heat source

For either countertop or range-top two versions the primary heating methods for the plates are through either direct gas-fired flame (natural gas and propane are typical), or via high-powered electrical elements. While gas-fired appliances are typically acknowledged to have faster response and more control, these characteristics are a function both of the heat source and the plate material. Plate material with a sufficiently high heat transfer coefficient can exceed the performance of a steel plate heated by gas, even if heated by electrical elements.

Gas

Gas griddles are by far the most common, due to the ready availability of natural and propane gas in commercial cooking environments, and are preferred for their rapid heat-up and more consistent temperatures. Gas burners will tend to heat the plate more evenly as a film of hot gases will cover the entire bottom plate surface. Typical griddles use between 25,000 and 30,000 BTU of energy per linear foot.

Electric

Electric griddles are typically made of a thinner plate material than a similar gas griddle to improve the heat transfer between the bottom-mounted elements and the cooking surface. Elements used to heat the griddle are typically 4-5 kilowatt (kW) per linear foot, and made from round rod sheathed incoloy material whose geometry is designed to optimize temperature distribution across the plate. The round elements have a tangential point of contact with the griddle plate and are commonly held in place by a clamping bracket or plate. More than one element per linear foot is common, and an array of these elements is required to heat a griddle plate of any given width. Electric griddles tend to be less expensive than a gas unit of similar size, due largely to the reduced plate thickness, but also the generally lower cost of construction and reduced sophistication of most electric griddle control systems.

Though they tend to lag their gas counterparts in productive capacity, an advantage to electric griddle construction is the relative simplicity of the system that tends to limit failure modes and can result in long life expectancy for these products. The lack of hot effluent gases can significantly reduce kitchen heat loads, and reduce overall kitchen system costs by exchanging a major gas heat source for an appliance with lower hood requirements. Rates for gas and electric utilities can be used to balance the cost of ownership decision in an appliance purchase, as some geographic areas have a combination of higher natural gas prices and lower electric prices that may make electrical appliances a more effective choice.[16]

Temperature control

Depending on the application a griddle may have either manual gas control or one of several types of thermostat in both gas and electric griddles. These control types have different performance characteristics based on the heat source, mounting, plate material and material thickness, and cannot be considered in isolation when making performance decisions.

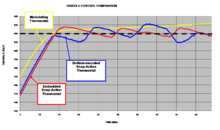

Thermostatic

Thermostats are used to regulate the griddle surface around a temperature set point established by the operator. Ranges of operation can vary depending on the controls used and the construction of the griddle, but 200 to 450 °F or 93 to 232 °C is most common. Other than solid state controls, which are very sensitive across their entire range of control, snap-action and modulating (aka – throttling) thermostats have peak sensitivity across the middle two-thirds of their operating range. This can limit their overall performance at the low end of their temperature spectrum (at or below 225 °F or 107 °C). This is due to the nature of the temperature control mechanism, which consists of a fluid-filled bulb (typically an oil) connected to the thermostat control via a long narrow capillary tube. The fluid in the bulb expands and contracts with temperature, activating a control response from the thermostat. There is a time lag between sensing the temperature change from the surface of the griddle plate to the response of the fluid within the bulb, to the thermostat control and turning the heat source on or off, up or down. This lag is referred to as hysteresis, and is a primary aspect of recovery time – an important griddle performance metric.

Most commercial griddles have a single thermostat control for every 12 in (305 mm) of unit width, though some may have only one thermostat for every 24 in (610 mm). This construction technique reduces unit cost by limiting the number of expensive control elements, but at the expense of performance and zone control. The thermostat control will not react quickly (if at all) to a surface load that is not relatively close to the probe, whether embedded or bottom mounted, resulting in less control and wider temperature variations on the cooking surface. Many griddle-cooked food portions are 5 in (127 mm) or less in diameter, meaning the distance from probe to the center of a load can average up to 8 in (203 mm) – a very long distance for heat transfer in steel.

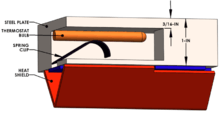

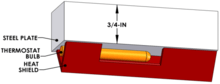

Bottom-mounted versus embedded

Reduction of the hysteresis in a griddle system is typically the difference between lower priced griddles and higher performing models, and can be accomplished through a combination of plate material, geometry, temperature controls and control location relative to the plate surface. Because thermostat mounting is internal to griddle construction it is necessary to compare of specification sheets for different griddle models, or griddles produced by different manufacturers, to determine which technique was used for a given griddle.

The most common construction for countertop griddle and range-top griddle thermostat applications is to fasten the bulb to the bottom of the griddle plate and protect the bulb from direct contact from the heating element (gas or electric) so that it can sense the change in the plate temperature. This is referred to as a “bottom mounted” thermostat, and discounting the control type, will result in the longest response time due to the thickness of the material. In general, if no mention is made of thermostat mounting or proximity to the griddle surface, the thermostat is bottom mounted.

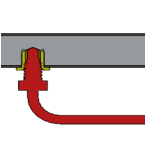

A common technique to reduce the time-to-response of a thermostat is to mill a slot into the bottom side of a griddle plate and “embed” the thermostat bulb in closer proximity to the griddle surface. This construction reduces the thermostat response time in approximate proportion to the distance to the griddle surface. Specification sheets or product literature will indicate embedded construction through use of key words like ‘embedded’ or indicate a specific probe proximity to the plate surface that is less than the plate thickness.

Solid state

Solid-state controls are used in gas and electric applications at the high range of the performance and cost spectrum. Composed of two parts, the sensor probe and the control box, solid state thermostats are the most precise control available for griddle operation. The probe consists of two thermocouple wires mounted in a protective capillary tube body that is mounted (typically threaded) into the griddle plate material at a location near the center of the heating element being controlled. When a temperature variation is detected the probe sends an electrical signal to the control box, which consists of an electrical circuit board that then activates or deactivates the burner system. This control system can respond almost instantly to temperature changes on the griddle surface, which provides a far superior temperature control response to the fluid filled capillary bulb found in Modulating and Snap Action thermostats. Temperature consistency to set point of +/- 5F is typical.

Temperature consistency across a griddle surface can be tightly controlled using this type of thermostat, making it ideal for high production environments where product uniformity and consistency are critical, as much for ease of operation as food quality. Owing to the electronic components, controls of this type are much more expensive than simpler, more mechanical systems. They are also more sensitive to grease and water infiltration that can damage the sensitive electronic components, and tend to have a lower temperature threshold, making insulation and ventilation more important in the griddle design. Surface temperatures for griddles using solid state thermostats are typically limited to 450 °F or 232 °C for this reason.

Snap-action

Snap action thermostats are the most common control used in heavy duty commercial griddles with medium-to-heavy production demands. These controls are called “snap action” because the control mechanism will turn the burner valve or electrical element fully on or completely off, with no modulation or intermediate heat source operation – effectively ‘snapping’ the heat source on or off. While not as responsive as solid state controls, snap action controls can maintain a griddle surface temperature within +/- 15°F (8°C) of set point if the thermostat bulb is embedded assuming a 1-inch (25mm) thick steel plate. This operating temperature range may be pushed to +/- 20 to 25°F (10°C to 13°C) if the probe is bottom mounted due to the additional thermal hysteresis introduced by the plate material.

Snap action control systems are often run with electricity, where a stand-alone thermostat acting as a switch is activated by the capillary bulb fluid. The thermostat switches an electrical signal on-or-off to an associated solenoid valve, controlling gas flow to the burner. This construction allows integration of other control mechanisms into the system, such as pilot flame failure, but requires the use of components known to be sensitive to high temperatures and water damage. Solenoids and associated wiring are known to degrade over time, even if operating within their design parameters, due to the cumulative effects of thermal cycling and ambient grease and oil coating their surfaces – environmental aspects known to attack the integrity of plastics.

Mechanical snap action thermostat valves are the integration of the control mechanism with the flow control valve. These devices have the same performance characteristics of the electrical system counterpart, but without the need for electrical wiring and the associated caveats. Pilot safety protection can also be integrated into control systems that utilize these devices, which can result in a wholly mechanical alternative to the electrical system. Appropriately designed, mechanical system are less sensitive to heat, water and grease infiltration, and so allow for a higher operating temperature range; up to 550 °F or 288 °C.

Modulating

The modulating thermostat, also referred to as the throttling thermostat, is the most basic thermostat control offered in the commercial griddle market and is typically found in lower priced griddles where some control is necessary but performance is not critical. It offers the advantage of being a mechanical system that doesn’t require electric power, which simplifies design and reduces overall unit cost. In this particular style of control the fluid in the bulb expands and contracts with temperature and slowly actuates an internal diaphragm which controls gas flow to the burner. One drawback to this control is long response time, which causes the overall control to overshoot and undershoot the temperature target by as much as 40°F (22°C). For example, at a set point of 350 °F or 177 °C, the griddle surface temperature over the probe can range from 310 to 390 °F or 154 to 199 °C.

Another important aspect of this control is the bypass flame setting, which allows gas to bypass the control of the thermostat diaphragm and allows the burner to operate irrespective of thermostat set point. If the bypass setting is too high and the griddle plate is not being cooled by cooking loads, the surface temperature of the griddle can drift well beyond the thermostatic set point.

Manual

Griddles with manual controls require constant attention by an operator to control the temperature of the griddle plate. Without food products to remove the heat from a griddle surface, the unregulated heat source can cause the plate surface temperature to rise continuously until it levels out at temperatures well beyond those normally used for cooking (over 750 °F or 399 °C). At these temperatures the griddle plate material may take on a bluish tint as the surface of the carbon steel plate oxidizes. Manual controls are not typically used on electric griddles.

Commercial applications for griddles using manual controls are varied, but often include menus that call for scorching proteins such as chicken or steak, or dry cooking products such as buns or tortillas. A common variation on griddles using this control is to have the surface of the griddle grooved in such a way that allows for the food product to retain grill marks, much as may be made when cooking on a charbroiler.

A common side effect associated with the unregulated temperatures of these griddle products is for the front rail of the griddle plate (sometimes called a “bullnose”) to become exceptionally hot - often well in excess of surface temperature criteria outlined in UL 197 Section 50.2. This area of the griddle is open to casual contact by an operator, and can often lead to burns on unprotected skin. Some manufacturers have incorporated unique designs, sometimes called “cool bullnose technology”, to minimize temperature excess in this zone and reduce the potential for operator injury.[17]

Accessories

There are many variations on the standard griddle, and accessories abound. Examples include stainless steel cabinets, refrigerated bases, adjustable legs, belly bars, and even cutting boards, to name a few. Cleaning accessories include such items as griddle scrapers and squeegees.

Commercial griddles can often be purchased with a variety of accessories, many of which are customized to the construction and manufacturer. Plate rails, condiment rails for holding standard kitchen pans (1/6 pan size is common), and cutting boards are among the most common.

Safety

Some gas griddles come equipped with a flame-failure safety device, but like many pieces of kitchen equipment, griddles can pose a fire hazard if not properly maintained. Care needs to be taken to keep the griddle and the area around it free of grease buildup. Splash guards at the edges of the griddle can help prevent grease from escaping to the surrounding workspace, and emptying the grease trough often helps prevent grease overflow. Additionally, because portable griddles are easily moved from one location to another, care must always be used to ensure that there is sufficient clearance between the griddle location and combustible materials. Also, common household griddles should not be located in a place where the heat control of the appliance would be accessible to children and others unfamiliar with the griddle's operation.

Commercial griddles are often required to have pilot protection (also known as “flame safety”) to prevent the unregulated flow of gas if the griddle pilot burners are somehow extinguished. This protection system can be electro-mechanical in nature, electrical, or electronic. All of these systems detect the presence of a pilot flame through a proximity sensor, which then allows or disallows gas flow to the burner valves based on the signal. Valves cannot then allow gas to flow to the burners if there is no pilot burner to ignite the gas, mitigating a safety hazard.

See also

References

- ↑ "Griddle". About.com. April 4, 2011. Retrieved October 17, 2015.

- ↑ "Griddle". (etymology). Online Etymology Dictionary. Retrieved November 1, 2011.

- ↑ "Griddle". TheFreeDictionary.com. Retrieved October 17, 2015.

griddle (ˈɡrɪdəl) n 1. (Cookery) Also called: girdle Brit a thick round iron plate with a half hoop handle over the top, for making scones, etc

- ↑ "Archive - At Home on the Farm". NEFA - The North East Folklore Archive - Junior Section. Aberdeenshire Council. Retrieved August 2, 2011.

- ↑ "Scran - Cooking oatcakes, or bannocks, on a girdle. Turnabrain, Glenesk, Angus, 1967". Retrieved August 2, 2011.

- ↑ Janice Cha (August 1, 2011). "SHORT REPORT: Griddle Me This!". Food Service Equipment Reports. Retrieved November 1, 2011.

- ↑ "Jade JGTSD Gas Griddle Performance Test" (PDF). Food Service Technology Center. Retrieved June 2003. Check date values in:

|access-date=(help) - ↑ "Technical Datasheet 304/304L Stainless". Carpenter Special Products Corporation. October 1, 2002. Retrieved November 1, 2011.

- ↑ William Fender, Medical Application Engineer. P.E. (January 2005). "Improved Stainless Steels for Medical Instrument Tubing". Carpenter Special Products Corporation. Retrieved November 1, 2011.

- ↑ "Rapid Recovery Griddle – Pancake Test". VulcanEquipment.com. Retrieved November 1, 2011.

- ↑ "ASTM A36 Steel, plate". www.matweb.com. Retrieved November 1, 2011.

- ↑ "Aluminum, Al, plate". www.matweb.com. Retrieved November 1, 2011.

- ↑ Pollution Prevention Technology Profile Trivalent Chromium Replacements for Hexavalent Chromium Plating, Northeast Waste Management Officials’ Association, 2003-10-18, archived from the original (PDF) on 2010-08-06.

- ↑ Degarmo, E. Paul; Black, J T.; Kohser, Ronald A. (2003), Materials and Processes in Manufacturing (9th ed.), Wiley, p. 793, ISBN 0-471-65653-4.

- ↑ QQ-C-320B

- ↑ "Market Attractiveness, Electric Cooking Based on Average Electricity and Gas Prices" (PDF). Food Service Council. September 2010. Retrieved November 1, 2011.

- ↑ "Table of Contents for UL 197". Underwriters Laboratories. Retrieved October 27, 2011.