GL Mk. III radar

GL Mk. III(B), with IFF | |

| Country of origin | UK |

|---|---|

| Introduced | late 1942 |

| Number built | ~1550 |

| Type | AA direction |

| Frequency | 2.750–2.855 GHz |

| PRF | 420 |

| Beamwidth | ~10 degrees |

| Range |

32,000 yards maximum, 27,000 yards against a light bomber |

| Precision | ±25 yards, ±1/6th degree at 32,000 yards |

| Other Names | Radar, Anti-Aircraft, No. 3 |

Gun Laying radar, Mark III, or GL Mk. III for short, was a radar system used by the British Army to directly guide, or lay, anti-aircraft artillery (AA). The GL Mk. III was not a single radar, but a family of related designs that saw constant improvement during and after World War II. These were renamed shortly after their introduction in late 1942, becoming the Radar, AA, No. 3, and often paired with an early warning radar, the AA No. 4, which was also produced in several models.

The Mk. III began development shortly after the introduction of the cavity magnetron in early 1940. The magnetron allowed radar systems to operate at microwave frequencies, which greatly reduced the size of their antennas and made them much more mobile and accurate. Having originally started work on the magnetron as part of the AI Mk. VIII air-to-air radar, the team was told to drop everything and develop a radar for AA use as quickly as possible. This turned into a fiasco; by the end of the year very little progress had been made and the team returned to working on airborne radars.

The magnetron has also been demonstrated to the Canadians and US as part of the Tizard Mission in the fall of 1940. Immediately following the visit, the National Research Council of Canada began development of a GL radar based on the UK design. The first examples of these GL Mk. III(C) (for Canadian) arrived in the UK in November 1942. British units of slightly more advanced design, GL Mk. III(B) (for British) arrived in December. 667 of the Canadian models were produced, with about 250 of these seeing service in the UK while most of the others were sent to the continent or remained in Canada. 876 of the British models were produced and saw more widespread service. Fifty Mk. IIIs were supplied to the Soviet Union.

Several improved versions of the Mk. III(B) were experimented with, but none were widely produced due to the 1944 introduction of the SCR-584 from the US, which provided both scanning and tracking in a single semi-trailer unit. Mk. III units found themselves relegated to secondary roles, as diverse as artillery spotting, coastal surveillance and weather balloon observation. Several upgrades were carried out for these roles, and modified weather units remained in use until about 1957/58. More radical development of the design also led to the greatly improved post-war AA No.3 Mk.7 radar, which served as the Army's primary AA radar until the removal of AA guns from service in the late 1950s.

Development

Earlier systems

The Army began serious research in radar systems in 1937, after being introduced to the developments made by the Air Ministry at their experimental station at Bawdsey Manor. Among several possible uses for radar, the Army saw it as a way to address the pressing need to accurately measure the range to aerial targets. This was being handled by optical means that were difficult, time consuming and error prone, and a radar system could dramatically improve this task. The development team, nicknamed the "Army Cell", was set the task of building a system that would provide slant range measurements with an accuracy of 50 yards (46 m) or better.[1]

The result was an unwieldy system known as the GL Mk. I radar. The Mk. I, like the Chain Home technology it was based on, used separate transmitter and receiver antennas that had to be moved in unison to track targets. The system did not provide an accurate bearing measurement, and had no provision for measuring elevation. It did, however, meet the requirement for 50 yard accuracy in range, a measure that was automatically fed into the analog computers that handled the ballistics calculations. Performance of the guns improved immediately; before the arrival of the Mk. I it was estimated that 41,000 shells had to be fired to achieve one destroyed aircraft, Mk. I and improved training reduced this to 18,500 by late 1940.[2]

Plans to add bearing and elevation measurements had been planned for a Mk. II version, which would be ready some time in 1941. As it became clear that the need was more pressing, Leslie Bedford of A.C. Cossor suggested adding an elevation system to the Mk. I to get it into the field as soon as possible. This became the GL/EF system, which reached service in early 1941 and resulted in a huge decrease in rounds-per-kill to 4,100, making AA effective for the first time. Mk. II, which offered slightly higher accuracy, reduced this further to only 2,750 rounds-per-kill when it began to arrive in 1942.[2]

Microwaves

The main reason for the unwieldiness of the early GL systems was a side-effect of the radio frequencies they used. GL had been designed in an era when the only electronics available were being adapted from commercial shortwave radio systems, and operated at wavelengths on the order of 5 to 50 m. It is a basic outcome of radio physics that antennas have to be roughly the size of the wavelength being used, which in this case required antennas several metres long.[lower-alpha 1]

The Admiralty had been placed in charge of vacuum tube (valve) development for the war effort.[3] They were particularly interested in moving to much shorter wavelengths as a way to detect smaller objects, especially the conning towers and periscopes of U-boats. The Air Ministry's Airborne Group, led by Edward George Bowen, had the opposite problem of desiring antennas small enough to mount in the nose of a twin-engine aircraft. They had managed to adapt an experimental television receiver to 1.5 m, but this still required large antennas that had to be mounted on the wings. At a meeting between Bowen and the Admiralty Experimental Department's Charles Wright, they found many reasons to agree on the need for a 10 cm wavelength system.[4]

Given the support for microwave development from both services, Henry Tizard visited the General Electric Company's (GEC) Hirst Research Centre in Wembley in November 1939 to discuss the issue. Watt followed up with a personal visit some time later, leading to a 29 December 1939 contract for a microwave AI radar set using conventional tube electronics. Meanwhile, the Admiralty's Communication Valve Development Committee (CVD) approached Birmingham University to develop entirely new tube designs that might lead to better results.[5]

Magnetrons

.jpg)

Birmingham's Mark Oliphant initially attacked the problem by attempting to further develop the klystron, a pre-war invention that was one of the first successful microwave-frequency tubes. In spite of many attempts, by the end of 1939 their best klystrons were generating only 400 watts, far below what would be needed for radar use.[5] Two minor members of the team, John Randall and Harry Boot, had been asked to look at other concepts which also failed to mature. Left with little to do, they begin considering alternative solutions. They struck upon the idea of using multiple resonant cavities arranged in a circle outside a common central core, as opposed to the klystron's linear arrangement. Their very first cavity magnetron produced 400 W, and was pushed to over 1 kW within a week. Within months, GEC had models producing pulses at 10 kW. These were soon being used in the design of a new airborne radar system initially known as AIS, for Airborne Interception, Sentimetric [sic].[6]

The Army, meanwhile, had visited GEC on several occasions during 1940 and seen their progress using conventional tube electronics at shorter wavelengths. In a series of steps, GEC had managed to reduce the operating wavelengths of their systems from 1.5 m, the original airborne radar frequency, to 50 cm, and later to 25 cm. These could be used in a directional system with an antenna a metre or less in size. In contrast to the Airborne Group, who needed even shorter wavelengths to make very small antennas that could fit in the nose of an aircraft, or the Navy, who needed a system with enough resolution to pick up periscopes, the Army was looking only for a practical improvement in accuracy and smaller antennas. This could be met with GEC's solution, and by the middle of 1940, the Army's Air Defence Experimental Establishment (ADEE) was working on a system using a klystron transmitter and a receiver from British Thomson-Houston (BTH), who had built the earlier 5 m GL sets.[7]

Klystron failure

When Albert Percival Rowe, director of the Air Ministry's radar teams, heard of the Army efforts in September 1940, he set about creating his own GL development effort using the magnetron. After a 22 September meeting with Philip Joubert de la Ferté, a senior commander in the RAF, Rowe built a GL team under the direction of D. M. Robinson using several members of the AIS team, telling them that they would have to focus on the GL problem for the next month or two.[7]

This led to increasing friction between Philip Dee, who ran the AI team's magnetron efforts, and Rowe, in overall command of the Air Ministry researchers. Dee claimed that Rowe was "seizing this opportunity to try and filch the GL problem from the ADEE" (the Army Cell) and that "only Hodgkin is carrying on undisturbed with AIS, and Lovell and Ward are fortunately engaged upon basic work with aerials and receivers and are therefore relatively undisturbed by this new flap."[7] According to Lovell this did not represent as much of a disruption as Dee believed. Moreover, to some extent, the klystron work at Birmingham had continued because of the Army's GL efforts.[8]

The main issue for adapting the AI concepts to the GL problem was that of angular precision. In the case of AI, the radar operator was able to track the target with an accuracy of about 3 degrees, improving to as much as 1 degree at close range.[9] This was more than enough for the pilot to see the target close to dead-ahead once they approached to within about 1,000 feet (300 m). For gun laying at long range the operators might never see the targets, so precision has to be at least 1⁄2 degree, and 1⁄10 would allow the guns to be directed solely by the radar.[10]

The solution to providing much higher angular accuracy was already known, a technique known as conical scanning. Shortly after Lovell began working on such a system, Edgar Ludlow-Hewitt, Inspector General for the RAF, visited the Rowe. After the visit, Rowe told the team that a complete GL set had to be ready for fitting to a gun in two weeks.[8] By 6 November Robinson had assembled a prototype system, but by 25 November he sent a memo to Rowe and Lewis (Rowe's assistant) stating that in the last 19 days, the system had only worked for 2 days due to a wide variety of problems. In December he was told to take the work completed so far to BTH for development into a deployable system. On 30 December 1940, Dee commented in his diary that:

| “ | The GL fiasco has ended up with the whole thing being moved en bloc to BTH, including two AMRE staff. Nothing ever worked properly at Leeson and Robinson is feeling that it has been very salutary for Lewis to learn how haywire all the basic technique really is.[8] | ” |

Magnetron GL

As part of the Tizard Mission in August 1940, an early magnetron had been demonstrated to representatives of both the US's National Defense Research Committee (NDRC) as well as the Canadian National Research Council (NRC). The US and Canadian teams soon set up permanent contacts and split up their efforts to avoid duplication of work. A staff of six Canadians on loan from the NCR remained at the Radiation Lab through the war.[11]

On 23 October 1940, the NRC team received a telegram from England asking them to begin work on a GL system using a magnetron.[11] They asked for a tracking range of up to 14,000 yards (13,000 m) with a range accuracy of 50 yards (46 m), although they desired it to be 25. They also wanted a search mode of unspecified range, with a range accuracy of 250 yards (230 m). Angular accuracy had to be at least 1⁄4 degrees in both axes, but 1⁄6 was desired. All of the outputs had to directly drive magslips.[10]

Oddly, given the rudimentary state of radar development at the NRC at that time, the UK was largely absent from further development. Although information about the GL system's development continued to flow to Canada, little economic or scientific support was given until 1943, when the NRC greatly expanded its liaison office in London. This lack of coordination would severely delay Canadian production of many radar systems.[12] In contrast, the Canadian-US liaison team had already agreed that the US should concentrate on a more sophisticated system while the Canadians worked on their basic design.

Adding to the confusion, by January 1941 the Ministry of Supply gave up on the ongoing Army efforts in the UK and released a new specification for GL based on a magnetron.[8] This meant that the earlier effort to develop a conventional transmitter had been wasted. On the upside, by this time magnetron supplies were improving, and using one would produce a radar working at even shorter wavelengths and much higher power, improving both range and accuracy. BTH eventually delivered an experimental set on 31 May 1941,[lower-alpha 2] although this was far from a field-ready system.

GL Mk. III(C) design

The Canadian design became known as the Accurate Position Finder, or APF for short. At the time, the solution to rapidly switching a microwave signal between two antenna leads had not been solved. As a result, there was no way to use a single antenna for both transmission and reception, and the team initially considered systems with one transmitter and one receiver, or a single transmitter and four receivers. This profusion of antennas was not a major problem in the GL role; the reflectors were about a metre across, which was not too large for a ground-based system, especially considering the multi-metre wide antennas of the GL Mk. II it would replace.[13]

At the time no one knew "how to design a waveguide with a low-loss rotating point",[14] so the problem of feeding the microwave energy from the magnetron to rotating antennas had no obvious solution. Instead, they decided to adopt the solution used for the earlier GL sets, and mount their entire electronics van on a bearing plate and point it in the required direction. This greatly complicated the trailer, and the fragility of the under-designed trailers was a major problem for Australian users.[15]

Lacking a suitable early warning radar similar to the British Army's MRU's, the NRC also developed a second radar system known as the Zone Position Indicator (ZPI). This was rapidly developed using the basic design copied from the ASV Mk. II radar that had been supplied as part of an effort to begin production of ASV radars for the US Navy and Coast Guard. The ASV sets were based on conventional tube electronics, and operated in the 1.5 metre band that was common the early-war UK radars. As the APF operated at 10 cm, the two sets did not interfere with each other, and could be operated only meters apart. In operation, the ZPI would feed information to the APF, who would use this information to seek out the targets. The ZPI was the first radar of entirely Canadian design.[16]

In spite of the lack of close coordination with their British counterparts, the NRC had completed development of their version of the GL system in June 1941.[11] The first full demonstration of the complete system was made to Canadian officials on 27 June 1941, and again to visiting US officials on 23 July. At that time, the chief engineer of Westinghouse proved extremely impressed, and noted to a member of the NRC "that his company would not have believed that what we had done in nine months, could have been done in two years."[16]

GL Mk. III(C) production

While off to a great start in design terms, production of the units soon ran afoul of a peculiar Canadian wartime problem. Just after the opening of hostilities, General Andrew McNaughton, commander of the Canadian forces in Europe, urged that the government set up a company to supply the Canadian forces with various optical equipment like binoculars. These had been in short supply during World War I, and McNaughton was trying to ensure the same problem did not occur again. C.D. Howe, the Minister of Everything, set up a new Crown Corporation, Research Enterprises Limited (REL), to fill this need.[17] REL had proven up to the task in the optics field, but when they expanded into electronics, trouble began.[18]

The first order for 40 GL sets had been placed in January 1941, before the NRC had completed development. This order was followed by several additional orders from Canada, the UK, Australia, South Africa and others. Delivery dates were repeatedly pushed back as REL had problems delivering on several pre-existing contracts for other radar systems. The first production example didn't roll off the line at REL until July 1942, by which time it was clear there was an issue and pressure was put on the electronics division to speed up deliveries.[18]

The first shipment of GL sets reached the UK in November 1942.[18] When they arrived, the units were found to be completely unreliable. This led to a round of finger pointing between the NRC team and REL. REL complained that the NRC had worked over 300 change orders into the design while production was being set up,[16] filling a binder. The NRC, on the other hand, became convinced that the problem was due entirely to R.A. Hackbusch, director of the electronics section of REL. McNaughton became personally involved and had to call in Lt.Col. W. E. Phillips, director of REL, for a personal interview about the issues. He noted in his diary that Philips stated:

| “ | ...and said there was a general deterioration of the nerves these days, people were tired and there was a lot of loss of control... It was a very interesting interview.[19] | ” |

In an attempt to get to the bottom of the situation, Mackenzie of the NRC arranged for Col. Wallace to visit the REL on 11 November 1942. Wallace began to talk to people on the shop floor, and was eventually told by one superintendent that Hackebusch personally ordered him to concentrate on quantity rather than quality, so that the systems were not being tested before delivery. It also became clear that Hackebusch had hidden this from Phillips.[19]

In spite of this, and the continued failures in the field, no action was immediately taken to fix the problem. During a visit to Ottawa in March 1943, Phillips met with Mackenzie and Wallace and agreed the problem was real, admitting "all the weaknesses of Hackbusch and [said] they are going to make a fundamental change which we all know is overdue by at least two years."[19] Yet still nothing was done. It was not until 2 September that Philips was "forced to accept his [Hackbusch's] resignation". A week later, Wallace was given the job, although he remained Director of the Radio Branch at NRC as well. When Mackenzie visited REL on 30 March 1944, he reported that the company was completely reorganized.[20]

Adding to their problems, REL was constantly short of magnetrons, which were built by General Electric in the US, CRTs for the displays, or the multitude of other conventional vacuum tubes the system used. Then, in the middle of development, the UK demanded that the system be upgraded to support IFF use.[14] Lacking an IFF unit of their own, British sets were used, which proved to interfere with the ZPIs, which operated in similar frequencies.[21] In spite of all these problems, REL delivered 314 sets to the UK by the end of 1942, and these quickly replaced the older Mk. II sets at AA emplacements around the UK. The UK-based APFs formed the backbone of the London-area AA direction during Operation Steinbock in early 1944, the last concerted German bombing effort using manned aircraft.[22] One of the earliest uses for the III(C) in Canada was as a surface-search system to detect U-boats in the Saint Lawrence River.

By 1943 the need for the Mk. III units had dried up with the imminent arrival of the SCR-584 units from the United States. The UK cancelled its order in January 1944, which was a major blow to REL.[23] Of the 667 Mk. III(C)s eventually completed, 600 were sent to the UK, with about half of these were used in the field in Europe as mobile units, and the other half used at static emplacements in the UK. The small number of Mk. III(C)s sent to Australia proved almost unusable as delivered, and had to be extensively re-built in order to make them operational.[24]

GL Mk. III(B)

After the first experimental magnetron set had been delivered in April 1941, BTH continued development of their Mk. III design, introducing a Model B in July 1941. This led to an order for 28 hand-built prototypes, five of which were delivered between December and April 1942, reaching only eight by the end of the year. Along with the prototype order, an order for a further 900 production models had also been placed in July 1941. The first of these arrived in December 1942.

Since BTH's Mk. III(B) had its design frozen some time later than the Canadian model, it featured a number of improvements that produced a much more practical design. Foremost among these differences was the mounting the antennas on a large metal pole, the rotor, that projected through the roof and down to the floor of the trailer where it sat in a bearing. Instead of trying to rotate the microwave feeds, the III(B) mounted the radio frequency components on the mast, and then fed power to them via conventional brushings. This allowed the antennas, on top of the mast, to rotate easily under the control of the operator turning a large handwheel. This eliminated the need to rotate the entire cabin, and greatly simplified the carriage. A more minor change was the use of fabric covers stretched over the antenna and fastened to the outside edge of the parabolic reflectors. With the covers in place, the assemblies look like two flat disks, an easy way to tell them apart from the Canadian version.

The III(B) proved reliable in the field from the start. Deliveries picked up in 1943, and a second order for an additional 2,000 units was placed. However, total production during 1944 was only 548 sets. By this time the US SCR-584 was beginning to arrive and was considerably better than the Mk. III(B), so production was deliberately slowed. When production ended in April 1945, a total of 876 had been delivered.[25] Some of these also included interrogators for IFF Mk. 3, which can be distinguished by the two large whip antennas extending from the rear cabin roof.

GL Mk. III(B) versions

Mk. III(B) was upgraded several times during the production run, although these later versions are universally known by the later AA No. 3 Mk. 2 name, the Mk. 1 being the III(C).[lower-alpha 3]

The Mk. 2/1 version added automatic tracking that allowed the operator to lock onto to a target and then have the electronics automatically follow it with no further manual intervention. The /2 was a dual-mode system who's displays could be used for anti-aircraft or in the Coast Defense role. The /3 also had lock-follow, but used a model developed by AA Command rather than Army's Radar Research and Development Establishment (RRDE). The /5 was a /2 with the same lock-follow as the /3. The AA No. 3 Mk. 2(F) was an unmodified No. 3 used by the Field Army as a mortar locating radar.

It was the AA No. 3 Mk. 2/4 that achieved the only lasting use of the original Mk. III design. This was a AA No. 3 Mk. 2 with additional circuitry that allowed the timebase to be offset by the equivalent of 30,000 yards (27,000 m) or 60,000 yards (55,000 m). This provided three sets of ranges, 0 to 32,000, 30,000 to 62,000, and 60,000 to 92,000 yards. This version was used as a meteorological system for measuring the winds aloft by launching weather balloons with radar reflectors that allowed them to be tracked for extended periods. The Mk.2/4 was widely used into the late 1950s in this role.

Other GL radars

While development of the Mk. III dragged on, the Army began a crash program to develop an intermediate system using the same 1.5 m band electronics being widely used in other radars. Known as "Baby Maggie", it is unclear whether it was assigned a number in the original GL series, although it was named using the new nomenclature as the AA No. 3 Mk. 3.[27] It does not appear that Baby Maggie was ever used operationally, although a number of sources claim that 50 were sent to the USSR. Whether these are the same as the reports of the 50 GL Mk. III's being sent, or if 50 of the Baby Maggie and another 50 Mk. III(B) were sent, remains unclear. Some units saw post-war use in India for weather balloon tracking.[28]

Development of the Mk. III continued through the period while the SCR-584 was being deployed. This led to a new model in 1944, the AA No.3 Mk. 4, code named "Glaxo". Only a few models were produced during the last stages of the war. Further development of the same design under the rainbow codename "Blue Cedar" produced an extremely successful design that entered service as the AA No. 3 Mk. 7. Mk. 7 remained in use as the UK's primary gun laying radar until the large AA guns were removed from service in the late 1950s. The Mk. 7 was also used as the illuminator for an early beam riding surface-to-air missile, Brakemine.[29]

Description

This description is based on the British Mk. III(B) model. In general terms the Mk. III(C) would be similar, with the exception of details of the mechanical arrangement of the trailer and cabin.

Equipment layout

The Mk. III was built on a five-ton, four-wheel trailer made by Taskers of Andover. The cabin was built by Metro Cammell, a builder of railway carriages. The deck of the front 1⁄4 of the trailer was waist height, providing room for the front axle to steer during towing. Immediately behind the wheels the chassis stepped down, with the rear portion being closer to the ground. The main cabin was situated on top of this lower section, with fenders providing clearance around the rear wheels.

The radar antennas were mounted on a large metal pole extending from the top of the cabin. A complex framework just above the roof allowed the antennas to be rotated vertically, controlled by an arm mounted behind the right parabolic reflector (dish). The two dishes were mounted on either side of the pole, with a gap between them. IFF antennas, if mounted, extended from the two upper rear corners of the cabin. The higher front area of the trailer mounted a generator as well as wooden boxes for storage of spares and tools.

To set up for operation, the trailer was parked on suitably flat land and the brakes were locked. Three levelling jacks were then swung out from the trailer, one on either side at the front where the step in the chassis met the cabin, and another from the rear of the cabin. The jacks were then used to level the cabin using spirit levels. The radar dishes were then raised, the generator started, and operations could begin. The entire setup took about 20 minutes, with 3 minutes required to warm up the electronics.

The entire system, including trailer, weighed over 9 long tons (9,100 kg), was 14 feet (4.3 m) high with the antennas raised or 12.5 feet (3.8 m) with them lowered for transport, was just over 22 feet (6.7 m) long and 9.5 feet (2.9 m) wide, extending to 15.5 feet (4.7 m) wide with the levelling jacks deployed.

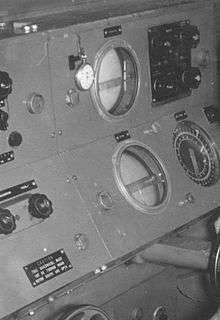

Displays and interpretation

1448.jpg)

The Mk. III used a somewhat complex multi-cathode ray tube (CRT) display system known as the Presentation Unit, built by The Gramophone Company (EMI).

Typical radar displays of the era measured range by comparing the blip of the return against its position on the CRT face. Measuring against a scale might offer range accuracy on the order of 200 to 400 yards (180–370 m) on the Mk. III's 6 inches (15 cm) CRTs, far less accuracy than needed for the gun laying role. To solve this problem, the Mk. III used two range displays, coarse and fine. The coarse display, placed about eye level in the console, was a classic A-scope display, showing all the blips within the range of the radar, normally 32,000 yards (29,000 m).

A large handwheel projecting from the console about knee level rotated a large potentiometer who's output was sent into a large capacitor. When the capacitor reached a pre-selected voltage, it triggered a second time base generator set to 6 microseconds, the time light travels 300 m, or in the case of radar's there-and-back round trip, 150 metres (490 ft). The output of this time base was inverted and mixed into the signal on the coarse display, causing an extended line to appear along the bottom of the baseline, known as the strobe. As the operator turned the handwheel, the strobe moved back and forth along the display, allowing the selection a particular target by centring it within the strobe.

This secondary time base was also sent to the fine CRT display, so that it showed only the blips within the 6 microsecond time window. On this 6 inch display, this meant that every inch represented about 50 metres (160 ft), offering much greater accuracy. In operation, the operator would continually turn the handwheel in an effort to keep the blip exactly centred in the display, as measured against a fine metal wire stretched over the face of the tube. This allowed continual range output with an accuracy on the order of 25 yards (23 m), more than accurate enough for the gun laying role.

This second time base was also used to trigger the elevation and bearing displays, so their displays showed only the single blip selected in the strobe. These operators, bearing sitting to the left of the range operator, and elevation to the left of him, had a single CRT in the upper panel, and a circular gauge displaying their measurement was moved to the location of the range operator's fine display on the lower section of the panel.

Although conical scanning allowed accurate measurement of the angle of the target, it did not directly indicate which direction to turn the antenna to center it – this could be seen in the rising and falling blip strength, but in practice this was far too fast to follow visually. For this purpose, the Mk. III adopted a display system known as a split line display on the CRTs. The output from the amplifiers was split into two output leads. One output is sent to the range display as normal. The second is fed into a mechanical switch that is synchronized to the rotation of the antenna, only connecting to a display input when the antenna is at certain points – when it is roughly horizontal it is sent to the bearing display, and when roughly vertical to the elevation display.

The switch also alternately sends the signal through a voltage inverter, causing the signal to alternate in which direction the blip with draw on the CRT. In the case of the elevation display for instance, the switch will cause the blip to be drawn above the baseline when the antenna is below the reflector centreline, and below the baseline when the antenna is at the top. The resulting display shows two blips for every target, on either side of the baseline. By comparing the relative lengths of the two blips, the operator can determine which direction the target is closer to; if the upper blip is longer they know the target lies above the current direction of the dishes, and he rotates his handwheel to raise the antenna until the two blips are the same length. The only difference for the bearing operation was that the time base on this CRT was rotated 90 degrees to provide a direct left/right indication.

Operational technique

Given the limited angle that the Mk. III scanned, 10 degrees at most, the system was normally paired with a second radar with a much wider scanning pattern. In the case of the AA No. 4, this provided a complete 360 degree scan that was displayed on a plan-position indicator. The operators of this second radar would call out contacts to the Mk. III operators, who would spin their antenna to the indicated bearing and then move the antenna vertically to find the target. When a blip was seen on the coarse range display, the range operator would move the strobe into position, and from then on all of the operators would move their controls continuously to create smooth tracking.

The range control was connected to a potentiometer and measured range electronically. The elevation and azimuth was measured via the physical position of the antenna. Turning the handwheels at these positions drove the rotor assembly through selsyn motors, and the current position was fed back to the operator display using magslips, better known today as synchros. The output of the magslips was also amplified and sent to external connectors, where they could be used to create additional displays at remote locations. These were placed in front of the operators of the gunnery analog computers, known as predictors, who would feed these numbers into the computer. The output of the computer was similarly fed to another set of magslip indicators placed in front of the gunners. The gunners then rotated the gun until their indicators lined up with those from the predictor, a technique known as laying needle on needle. The range was used for fuse timing, which was set automatically in a fuse setting machine driven directly off another magslip. In some cases the output of the radar drove the inputs of the predictors directly, and in others the outputs drove the gun laying directly, making the process highly automated.

IFF use

As early as 1940 some British aircraft were equipped with the IFF Mk. II system, and by the time the Mk. III radars were being introduced in 1943, many aircraft were equipped with IFF Mk. III. These consisted of a transponder installed on the aircraft that was tuned to a pre-selected frequency, and when it heard a signal on this frequency, sent out a short signal of its own on a different pre-selected frequency.[30]

GL Mk. III was optionally equipped with the corresponding interrogator. When the radar operator pressed a button, the interrogator would send out periodic signals on the selected frequency via a large whip antenna mounted at the rear corner of the cabin. The responding signal from the transponder was received on a second antenna on the opposite rear corner of the cabin, amplified, and sent into the displays. This signal mixed with the radar's own receiver, causing the new signal to be displayed directly behind the blip. Instead of a sharp bell curve like shape, a signal responding to the IFF challenge would have a rectangular extension behind it, allowing the operator to easily see which aircraft were friendly.[31][32] In practice, IFF selection was often handled by the search radar before they handed off to the GL, and the IFF fittings on GL were not universal.

Meteorological use

The Mk. III's longest lasting use was for meteorological measurements of winds aloft by tracking radar reflectors hung from weather balloons. To measure speed, a stopwatch was mounted near the range display and readings were made every minute.

As the balloons often blew out of the radar's nominal 32,000 yard range, these versions were equipped with a Range Extender device. This was a monostable multivibrator, known as a One-Shot or Kipp Relay, that triggered the coarse time base, offsetting its starting point so it did not trigger immediately after the transmission, but a selected time after that. The Extender had settings for 30,000 or 60,000 yards, so the system could track the balloons in three general windows, 0 to 32,000 yards, 30,000 to 62,000, and 60,000 to 92,000.

These units were produced after the naming had been changed, and were universally known as AA No. 3 Mk. 2/4.

Notes

- ↑ Finding a single reference that clearly states this well known fact is difficult, although the physics involved can be understood in the Friis transmission equation and the Chu–Harrington limit.

- ↑ Another source says the first GL set was delivered to Rugby in April 1941.

- ↑ The nomenclature appears to have been changed in the autumn of 1943 or 1944. The only reference to the renaming is a passing one in the histories of the No. 1 Canadian Radio Location Unit, which describes the unit being active for some time before being told their Mk. IIIC's "would be replaced during December". As the Mk. III(C) was introduced operationally in 1943 and replaced by the SCR-584 in early 1945, this suggests the renaming took place in late 1944.[26]

References

Citations

- ↑ Bedford 1946, p. 1115.

- 1 2 Austin 2001, p. 211.

- ↑ White 2007, p. 125.

- ↑ Bowen 1998, p. 143.

- 1 2 Lovell 1991, p. 35.

- ↑ White 2007, p. 130.

- 1 2 3 Lovell 1991, p. 48.

- 1 2 3 4 Lovell 1991, p. 49.

- ↑ AP1093D 1946, Chapter 1, para 54.

- 1 2 Middleton 1981, p. 129.

- 1 2 3 Dzuiban 1959, p. 285.

- ↑ Zimmerman 1996, p. 202.

- ↑ Middleton 1981, p. 130.

- 1 2 Avery 1998, p. 90.

- ↑ Blackwell 1994, p. 86.

- 1 2 3 Mendes 2012, p. 9.

- ↑ Middleton 1979, p. 42.

- 1 2 3 Middleton 1979, p. 43.

- 1 2 3 Middleton 1981, p. 44.

- ↑ Middleton 1981, p. 45.

- ↑ Middleton 1981, p. 81.

- ↑ Dobinson 2001, p. 394.

- ↑ Avery 1998, p. 91.

- ↑ Blackwell 1994, pp. 84–88.

- ↑ Burns 2000, p. 398.

- ↑ "No. 1 CRLU Radar History" (PDF). Canadian Army. p. 1.

- ↑ Austin 2001, p. 268.

- ↑ Raghavan, S. (2003). Radar Meteorology. Springer. p. 3.

- ↑ Duxford.

- ↑ AP1093D 1946, Chapter 6, para 11.

- ↑ AP1093D 1946, Chapter 6, para 12.

- ↑ AP1093D 1946, Chapter 1, para 37.

Bibliography

- "Radar Anti-Aircraft No. 3 MK. 7 – Blue Cedar (UK)". Duxford Radio Society.

- AP1093D: An Introduction Survey of Radar, Part II (PDF). Air Ministry. 1946.

- Avery, Donald (1998). The Science of War: Canadian Scientists and Allied Military Technology During the Second World War. University of Toronto Press. ISBN 9780802059963.

- Austin, Brian (2001). Schonland: Scientist and Soldier. CRC Press. ISBN 9781420033571.

- Avery, Donald (1998). The Science of War: Canadian Scientists and Allied Military Technology During the Second World War. University of Toronto Press.

- Bedford, Leslie (July 1946). "The development of gun-laying radar receivers type G.L. Mk.I, G.L. Mk.I* and G.L./E.F.". Journal of the Institution of Electrical Engineers. 93 (6): 1115–1122. doi:10.1049/ji-3a-1.1946.0199.

- Blackwell, John (1994). Choco to A.I.F. GeneralStore PublishingHouse. ISBN 9780919431836.

- Bowen, Edward George (1998). Radar Days. CRC Press. ISBN 978-0-7503-0586-0.

- Burns, Russel (2000). The Life and Times of A D Blumlein. IET. ISBN 9780852967737.

- Dobinson, Colin (2001). AA Command: Britain's Anti-aircraft Defences of World War II. Methuen. ISBN 9780413765406.

- Dzuiban, Stanley (1959). Military Relations Between the United States and Canada, 1939–1945. Department of the Army.

- Lovell, Bernard (1991). Echoes of War: The Story of H2S Radar. CRC Press. ISBN 9780852743171.

- Mendes, Brian (Fall 2012). "Last One Standing" (PDF). IEEE Canadian Review. 8–10 (6): 1115–1122.

- Middleton, William Edgar Knowles (1979). Physics at the National Research Council of Canada, 1929–1952. Wilfrid Laurier Press. ISBN 9780889200722.

- Middleton, William Edgar Knowles (1981). Radar Development in Canada: The Radio Branch of the National Research Council. Wilfrid Laurier Press. ISBN 9780889201064.

- White, Ian (2007). The History of Air Intercept (AI) Radar and the British Night-Fighter 1935–1959. Pen & Sword. ISBN 978-1-84415-532-3.

- Zimmerman, David (1996). Top Secret Exchange: The Tizard Mission and the Scientific War. McGill-Queen's Press. ISBN 9780773565975.

External links

- The use of GL3 Radar in the Met Office by Bill Wallace, explains the use of No.3 Mk.2/4 as a weather instrument.

- The Restoration of a Radar, AA, No3 Mk2, two derelict Mk. 2's are being turned into one restored version.

- Radiolocation (Radar) Unit GL III(c) contains a number of wartime images of a Canadian unit training on the Mk. III.

- This letter provides a complete outline of a GL Mk. III-equipped AA site.