2-Vinylpyridine

| |

| Names | |

|---|---|

| Preferred IUPAC name

2-Ethenylpyridine | |

| Other names

2-Vinylpyridine 2VP | |

| Identifiers | |

| 100-69-6 | |

| 3D model (Jmol) | Interactive image |

| ChemSpider | 7240 |

| ECHA InfoCard | 100.002.618 |

| PubChem | 7521 |

| |

| |

| Properties | |

| C7H7N | |

| Molar mass | 105.14 g·mol−1 |

| Appearance | Brown, clear liquid |

| Density | 0.977 g/cm3 |

| Melting point | −50 °C (−58 °F; 223 K) |

| Boiling point | 158 °C (316 °F; 431 K) |

| 27.5 g/L | |

| Vapor pressure | 96 hPa (72 mmHg) at 100 °C |

| Acidity (pKa) | 4.98 |

| Viscosity | 1.17 mPas |

| Hazards | |

| Flash point | 48 °C (118 °F; 321 K) |

| Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| | |

| Infobox references | |

2-Vinylpyridine is an organic compound with the formula CH2CHC5H4N. It is a derivative of pyridine with a vinyl group in the 2-position, next to the nitrogen. It is a colorless liquid although samples are often brown. It is used industrially as a precursor to specialty polymers and as an intermediate in the chemical, pharmaceutical, dye, and photo industries.[1]

Synthesis

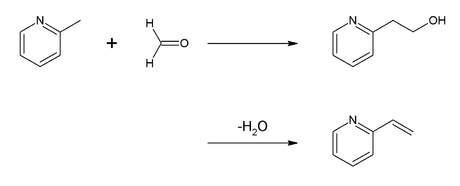

It was first synthesized in 1887. A contemporary preparation entails treatment of 2-methylpyridine with formaldehyde, followed by dehydration of the resulting intermediate alcohol. The reaction is carried out between 150–200 °C in an autoclave. The conversion must be kept relatively low with short reaction time to suppress the formation of byproducts. After removal of unreacted 2-methylpyridine by distillation, concentrated aqueous sodium hydroxide is added to the residue and the resultant mixture is distilled under reduced pressure. During distillation, the dehydration of 2-(2-pyridyl)ethanol occurs to give 2-vinylpyridine, which can be purified further by fractional distillation under reduced pressure in the presence of an inhibitor such as 4-tert-butylcatechol.[1]

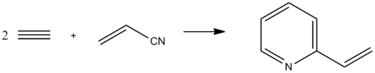

An alternative synthesis involves the reaction of acrylonitrile and acetylene below 130–140 ̊C in the presence of organocobalt compounds as a catalyst.[1] Acrylonitrile is the solvent for the reaction.[2]

Vinylpyridine is sensitive to polymerization. It may be stabilized with a free radical inhibitor such as tert-butylcatechol. Owing to its tendency to polymerize, samples are stored between 3-4 °C. It is incompatible with strong oxidizing agents, strong bases, strong acids.

Uses

Polymeric derivatives

2-Vinylpyridine is readily polymerized or copolymerized with styrene, butadiene, isobutylene, methyl methacrylate, and other compounds in the presence of radical, cationic, or anionic initiators. The homopolymer is soluble in organic solvents such as methanol and acetone, whereas cross-linked copolymers are insoluble in organic solvents.

The most common application of 2-vinylpyridine is for use in the production of a latex terpolymer of 2-vinylpyridine, styrene, and butadiene, for use as a tire-cord binder. The tire cord is treated first with a resorcinol-formaldehyde polymer and then with a terpolymer made from 15% 2-vinylpyridine, styrene, and butadiene. This treatment gives the close bonding of tire cord to rubber essential in the production of tires.

2-Vinylpyridine is a co-monomer for acrylic fibers. Between 1–5% of copolymerized 2-vinylpyridine provide the reactive sites for dyes.[2]

Organic synthesis

Due to the electron-withdrawing effect of the ring nitrogen atom, 2-vinylpyridine adds nucleophiles such as methoxide, cyanide, hydrogen sulfide at the vinylic site to give addition products.[1] The addition product of methanol to 2-vinylpyridine, 2-(2-methoxyethyl)pyridine is a veterinary anthelmintic.[1]

Treating 2-vinylpyridine with 4-pyridinecarbonitrile and hydrogen chloride gives 1-[2-(2-pyridyl)ethyl]-4-cyanopyridinium chloride, which then can be used to prepare dimethylaminopyridine (DMAP). DMAP is used are as a catalyst for acylation, alkylation, halogenation, cyanation, and silylation, and as an accelerator in the manufacture of polyurethanes.

References

- 1 2 3 4 5 Abe, Nobuyuki; Ichimura, Hisao; Kataoka, Toshiaki; Morishita, Sinji; Shimizu, Shinkichi; Shoji, Takayuki; Watanabe, Nanao. Ullmann's Encyclopedia of Industrial Chemistry 2007, p. 10-11

- 1 2 Bönnemann, H.; Brijoux, W.. Transition Metals for Organic Synthesis: Building Blocks and Fine Chemicals. 2008 (2), p. 188